Who we are

We have been in the sector for more than 25 years with our experience and know-how. We know the sector and its needs very well. We are customer focused. Our main goal is to be the solution partner of our customers with the principle of customer satisfaction.

What are we doing?

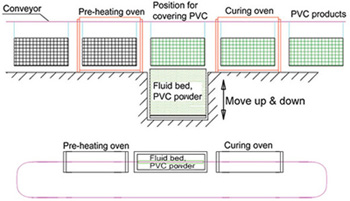

Complete powder coating plants

Complete wet paint facilities

Powder coating equipment

Overhead and floor conveyor lines

Process furnaces and coating systems

-

Infrared furnace systems with natural gas technology

Aging furnaces for aluminum extrusions

Wood effect sublimation systems

Project design and consultancy services

What distinguishes ELECTROGROUP from The Others

ELECTROGROUP is doing its job lovingly.

ELECTROGROUP work disciplined and programmed.

-

ELECTROGROUP are constantly investigating to be better.

-

ELECTROGROUP do not excuse, we produce solutions.